Thatch - villa "Sarnia" in Karpacz

During the preparatory visit, I was surprised by the poor condition of coverage, because the period of operation suggested that only the restoration of the ridge, minor repairs of the parts damaged by martins and cleaning the surface, or fire protection in the form of impregnation would be required ... At first sight it was obvious that unfortunately the beautiful location of the villa "Sarnia" also has its side effects - for sure degradation of the northern part of the roof has accelerated almost the merging of the building into the surrounding nature and the climatic conditions prevailing here.

The same was true of the western part of the roof, which in the lower part, in order to cover the adjacent terrace, was slightly raised, which causes deeper penetration of rainwater and accelerates the degradation of the reeds - but not all after eight years. Below you can see that the water has already carved out the canyons in the spreading reed ... The cause had to be different, but it will turn out to be done during the excavation! The southern side was in the best condition, although the areas of thatch below the windows..

Thatch - Renovation of the chimney

We try to inspect every possible source of problems in the future during the periodic service - it is better to make the necessary work before laying / repairing the cover, because any interference later shortens the life of thatch! It turned out that the chimney, which looked quite decent from the bottom, virtually absorbs all the rainwater that falls on it. A damp substrate is an excellent foundation for seedlings that have so rooted in a brick wall that in order not to disassemble the chimney, they could only be cut as far as possible.

It was soon possible to cover the entire chimney with a sheet of metal - this would cut off the path of moisture and prevent further destruction. In order not to remove this metal "hat", the reinforced mesh of the upper part of the chimney - a few-centimeter thick concrete slab will stabilize the surface of the chimney and fix the feathering. The flue gas vent was covered with a visor made of sheet metal. Now we were able to proceed to the implementation of the proper order - renovation of the reed roofing, which is below

Thatch - Roof ridge renovation

We started the service from the top - from the ridge. From there we will go down, measuring the thickness of the roof and checking the condition of the reed. After opening the ridge it was necessary to replace not only the filling material but also the undercoat. For this purpose, we use the NRO - polymer membrane on polyester canvas. On the foundation, we spread the copper fiber in order to slow down the development of moss and lichen on the floor below. The new fine-mesh mesh and heather filling - this is all the work on the ridge. The last action is the proper extension of the network - this will provide the necessary aesthetics

Below the ridge, the thatched roof was in the worst condition, although it moved a bit - the distance to the pressure rods guaranteed that there was still plenty of time to lie down, it was enough to thicken it well! Here I put in a description of the standard, which is the thickness of thatch above the pressure bar - it should make (for new thatch) about 15cm. In the case of old-fashioned thatch service, with a thickness of approx. 5 cm, it is still useful to clean and compact. With a smaller thickness and a healthy reed, leave the cover better for a few years and prepare for its replacement during this time.

Thatch - performance mistakes

Going down with the service we came to places where it was necessary to replace the thatched roof. Below are a few mistakes that are an infamous standard, and there are also errors resulting from the lack of any supervision plements the coverage. The contractor knew in advance that the thatch below the windows would bend quickly: the reason - the lack of continuity of waterproofing insulation. In the described case, the water from the copper sill was poured under the window sill underlay.

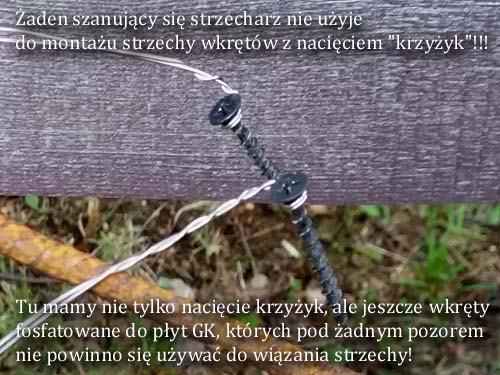

What can we see even lower in the pictures? Screws with a notch cross. Not only that - phosphatated screws for gypsum boards, which have a twice thinner rod from reed screws. I suppose it is a remnant of the team that was doing some repairs before us. The roof contractor used screws for thatch, but saved on a chrome-nickel wire using an ordinary steel wire, galvanized! This is why the reed slides out from under the pressure bars on most of the roof. Below, photos showing how the window sill should be made.

Thatch - window, unique!

In the picture below, we can see the northern part of the roof. Unfortunately, almost the entire site was so damaged that it was necessary to do it again. Here the executive errors (loose thatch, due to the use of ordinary wire) accumulated, too small distance to the trees, which hindered the air flow necessary for quick drying of thatch, and the independent factor overlapped - the northern side is always the least sunny. All this together resulted in the rapid development of moss on the wet cover, and consequently the total destruction which led to the leakage of rainwater through the cover

As you can see in the pictures 2/3 the length of the roof has been replaced. Higher, due to the greater air flow, the roof was still suitable for compaction. I wonder if you have noticed the unusual "roof window", and in fact it is not just the window that is interesting, but the solution to draining its surface. The window is mounted at the bottom of the roof cross-section and it is not possible to lead the rainwater to the surface of the thatched roof so that water can flow to the eaves after it. Here, the water drainage is specially made of sheet metal with a drain under the cover.

Thatch - effect our work

Well, I wrote enough above, focusing on the details. Now I leave you alone with the photos thatch after repair

Routinely work its finish installing the certificate of guarantee last glance at the beautiful scenery and move on ...

If you order a repair of thatch

We offer implementation of cane repair covering - thatched roof. We recommend contact even when the thatch fulfills its functions! In order to cooperate, please send the required information:

- roof surface;

- type of object;

- required security;

- planned date and time of completion;

- contact (telephone, address);

The term of the order depends on its time-consuming - it may be necessary to book a free time allowing for the execution of the order.

The cost of the service of thatch is dependent:

- from the size of the thatched surface;

- on the number of windows, chimneys, etc .;

- from the scope of work to be carried out (construction, security, insulation, compaction, cleaning, etc.);

- lokalizacji;

We issue invoices. In the case of real estate that meets the statutory conditions, a VAT rate of 8% is possible. We provide up to 10-year warranty for works made from scratch by our company!

Go to the inquiry form

- See also our gallery of inspiration - thatch from all over Europe!

- Find out the answer to the question: thatch - how to secure it!

- Thousands of service work performed by our company!